At Tell Akko, any square or area supervisor will be able to tell you that one of the ubiquitous finds is iron slag. Most squares that are undergoing excavation have at least one bag of slag coming out per day. Certain squares from seasons past, such as MM20, RR3, and most recently RR19 have been notorious for their ability to bring up kilos of slag or quintuple the amount of hammer scales that one might expect in a day. This isn’t just metal trash, however. When any object is created, there is a certain waste that is given off. While iron slag is by definition waste, by understanding the amount of slag that is given off we can attempt to gauge how much iron was being processed at the site and where it may have been coming from. In order to give insight to this process, we can track the story of an average piece of slag being recovered in a day of excavation on the Tell.

The first thing that a piece of Akko slag goes through (in the modern period, that is) is its excavation and discovery. Uncovering slag in situ on the Tell is always an exciting experience, because in many cases you are the first person to interact with it since it was deposited there almost 2,500 years ago. When students are digging, we give them a few pointers to help them identify slag accurately and effectively in the field.

The first key to field slag identification is the coloring of what otherwise looks like a normal rock. Although slag often acquires a very rocky look over the years, clear points of oxidation and rust will be apparent around the surface. These bright orange spots are dead giveaways to the true nature of what this so-called rock actually is. If it is not entirely clear by sight alone, and the slag has already fallen from its initial position, then weight is the next major hint. Slag, being comprised significantly of iron, is extremely dense. This means that relative to a rock of the same size, it should weight much more – unnaturally so. If both of these methods still leave the discoverer uncertain, there is one final test: the break test. True iron slag will not break in half from a hand-held breaking attempt; the metal is too strong. Many types of rocks or ambiguous materials will crack under this sort of pressure, however. Given a combination of these three tests, slag can be accurately diagnosed in the field.

Yuki finds a piece of slag in the field. See if you can find it just above the bucket!

A piece of freshly excavated slag. Small pockets of orange and an irregular shape are noticeable.

After the slag is identified, it is collected as excavation occurs around it. It is important to not to get too excited and dig a hole around the slag; rather, natural excavation should occur around the piece. The slag will always come out when it is ready.

From here, it is bagged and tagged for processing in the Small Finds area of the office, located at the academy where we are staying. While living in the pottery office, the slag is documented in our site wide database. Here, anyone working at the site is able to access information about any slag that was collected on any day, since the first day of excavation in the 2010 season. The Tell Akko database is what makes projects like mine, where the goal is to document and map all the slag found on the Tell, feasible.

A cross section and piece of slag in the pottery office. The coloration and porous structure characteristic of slag is clearly visible.

After this, the slag is taken across the Bay of Akko, where it is stored at the University of Haifa and can be accessed in the coming seasons. These store rooms hold information from the current Akko excavations, and even material dating to the excavations in the 70s and 80s. One of the main components to my project is poring over previous slag from other seasons and getting direct quantities and weights for the material coming from certain regions of the Tell. Once these weights are collected, there is one more (digital) step to the process.

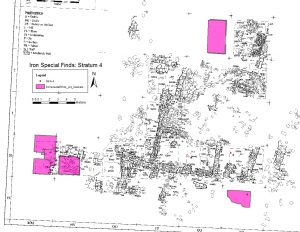

GIS, or Geographic Information Systems, are incredibly important in conveying information from a variety of disciplines. Archaeology is no exception. After creating artifact maps for Iron last season, my project this season is to map a slag distribution from this season and all previous seasons. These maps allow a comparison of various regions of the Tell extremely quickly, and gives a compact visual display to represent the incredible amounts of slag that we excavate from the Tell. With an easy to read format, these maps can be examined to determine relationships that might otherwise not be immediately apparent, and they help to increase our understanding of ironworking and production across Area A at Tell Akko.

GIS map showing Iron Artifacts found from stratum A-4 (Persian Period)

In addition to my work on macro-metallurgical remains, we are also conducting analysis of the elemental composition of soils across the Tell. But that is a blog for another time…

1 Comment